Ultraviolet light (UV) was discovered in the late 19th century. “Ultraviolet” is normally not perceptible to people, with a waveband shorter than visible light but longer than x-rays. There are several types of UV; UV-A, UV-B and UV-C, these occur naturally from the sun’s rays, but UV-C is usually blocked by the ozone layer which is why we are much more familiar with UV-A and UV-B as referenced on sunscreen products. UV-C is short waveband UV light and very effective at damaging or destroying the nucleic acids and DNA in microorganisms; with 254nm identified as the peak waveband for this purpose, described as Ultra-Violet Germicidal Irradiation (UVGI), this is considered a mechanical disinfection process as there are no chemicals at work. Destroying germs with UV light was used as far back as the 1920’s, to control outbreaks of Tuberculosis in the USA, obviously this technology has improved dramatically over the last century with previously unachievable levels of precision, reliability and performance.

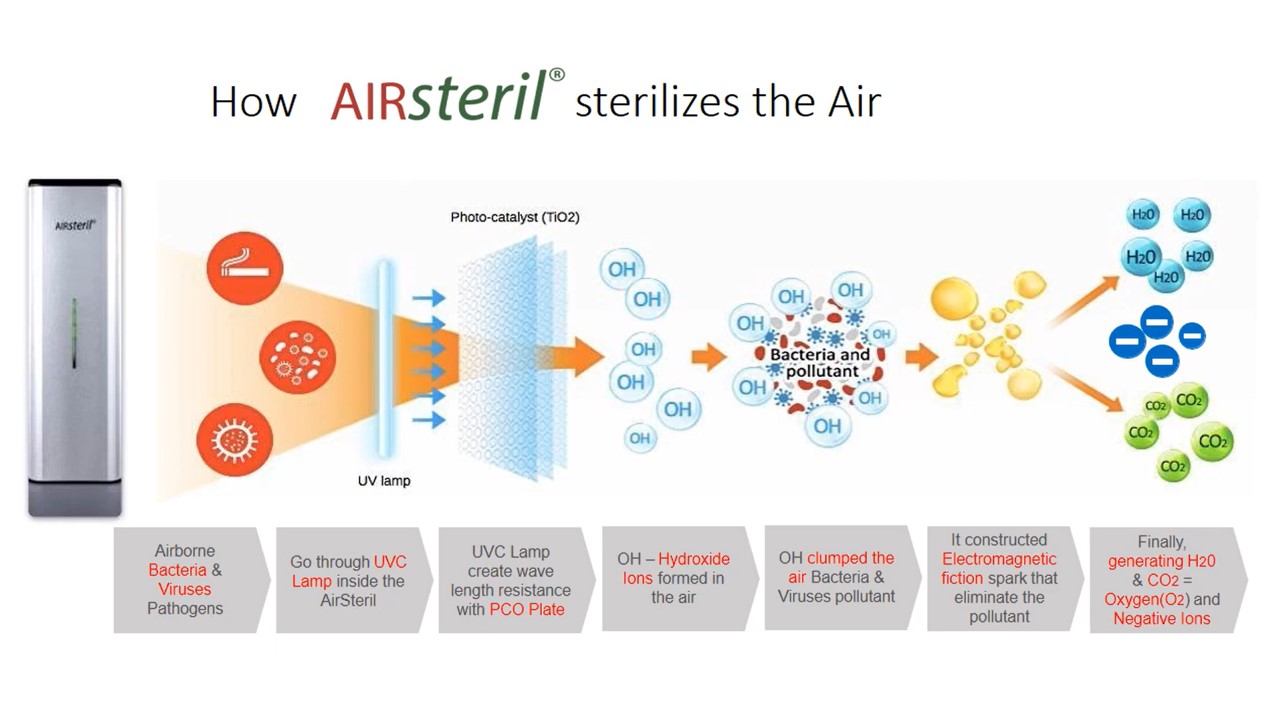

How AIRsteril® Technology Works

Germicidal Irradiation by dual UV light (Ultraviolet) kills microorganisms (bacteria, viruses and mould) by disrupting their DNA and removing their reproductive capabilities.

PCO – Photocatalytic Oxidation, UV reacts with our Catalyst (Ti02) to form highly reactive but short-lived oxidizing Hydroxyl Radicals (OH) which break down Volatile Organic Compounds (VOCs).

Interaction of the dual UV wavebands with the TiO2 heterogeneous catalyst both creates and breaks down Oxygen molecules transforming Oxygen into a highly reactive state of Ozone and Superoxide Ions which leave the unit as “Plasma Quatro”.

The negatively charged Superoxide Ions charge airborne contaminants causing them to cluster together and fall from the air as they become too heavy, aiding all other processes. This can remove airborne particulates down to 0.001 microns, that’s better than any HEPA filter.

Targeted Ozone produced via the specialist lamp assists other processes, boosting distribution of the sterilized air to ensure it is not repeatedly processed so contaminates are cleared effectively, and destroying unpleasant odors leaving a fresh and pleasant smell.

History of our Technology

Ozone is a highly reactive form of oxygen which oxidizes pollutants (uses its extra oxygen atom to destroy contaminates as it reverts to oxygen), particularly effective in clearing organic odors by breaking down compounds, at higher concentration ozone destroys microorganisms by damaging the cell walls. Discovered in 1840 by Christian Schonebein, one of the first Ozone uses was in water disinfection, with ozone generators developed for medical use through the 20th century. Ozone can be generated by several methods (maybe link to ozone article here or at end of paragraph) and it is essential that output is precisely controlled as it would be unsafe for people at higher levels. Ozone may be described as activated oxygen, atomic oxygen, triatomic oxygen, trioxygen or O3.

Photocatalysis is the acceleration of a chemical reaction using light. Photo Catalytic Oxidation (PCO) refers to the use of light energy to cause or speed up (catalyze) the oxidation of contaminates in air or water, this turns pollutants into harmless substances. The earliest reference to photocatalysis was in 1911, but by 1938 TiO2 (Titanium dioxide) in the presence of ultraviolet light was observed to produce active oxygen species, research continued with many branches of research now expanding the understanding and use of photocatalysis into multiple fields including “self cleaning” glass and concrete, water disinfection, sterilizing coatings and air sterilization. PCO can be particularly effective in breaking down harmful volatile organic compounds.

An AIRsteril air sterilizer utilizes a combination of the most effective and refined sterilization technologies to produce the best possible results. Every element of our process is adjusted across our product range to ensure the best results with varied chamber size, catalyst area and position, lamp output, dwell time and flow rate for each specific environment. In each unit, our dual ultraviolet light lamps operate at the peak UVC wavelengths in the presence of Ti02 catalyst plates enclosed within our reflective internal cleaning and sterilization chamber, creating germicidal irradiation, PCO – photocatalytic oxidation, hydroxyl radicals, superoxide ions and optional ozone with air leaving the unit as “plasma quattro”. This process freshens the air by killing airborne pathogens (viruses, bacteria, fungi and mould spores), breaking down organic compounds, reducing allergens and airborne particulates, alongside degrading and destroying odors.